SAM GUARD predictive analytics solution for the process industry quickly and accurately identifies equipment failures and suspicious operation modes days to weeks in advance. It provides early, accurate, and actionable alerts up to 5 times a day.

SAM GUARD’s combined technologies of AI and HI (human enhanced machine learning) enable you to achieve maximum availability, performance, and production.

SAVE MAINTENANCE COST, INCREASE AVAILABILITY

-

Covers the entire plant

Overall solution for monitoring – any equipment type and any vendor

-

Rapid onboarding

Up and running in 2-3 weeks. No additional sensors required

-

AMS

Our global team of process engineers will support you all the way through the project

-

Minimum false alert ratio

Due to patented algorithms and focus on equipment and processes

-

Data security

Due to on-premise server installation on site or certificated cloud installation

AI-BASED PREDICTIVE MONITORING

FOR THE

PROCESS INDUSTRY

SAM GUARD

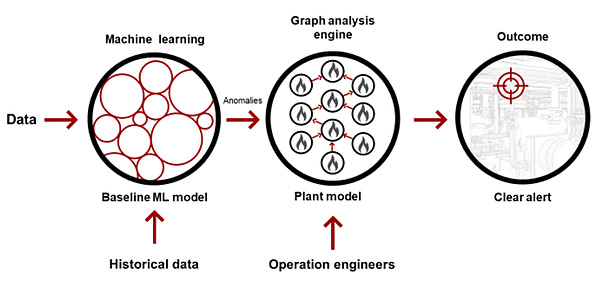

A POWERFUL COMBINATION OF ADVANCED AI SOFTWARE AND HUMAN DOMAIN KNOWLEDGE

- SAM GUARD’s AI-powered early alerts give you time to prepare a plan of action, long before the discovered issues make a significant impact on your plant. The earlier you catch a failure, the less it costs to repair, and the equipment is most often still recoverable.

- SAM GUARD uses AI to monitor your critical and regular equipment, both static and rotating, to ensure 100% coverage of all your assets.

- SAM GUARD uses both unsupervised and supervised AI to ensure alerting on known repeating issues in addition to discovering unknown issues without human guidance.

SAM GUARD

ANALYTICAL MONITORING SERVICE

- Our analytical monitoring engineers will support you during whole project period, starting from building plant Digital Twin, followed by continues analysis of SAM GUARD alerts, and will work with your team to review valuable findings

SAM GUARD CUSTOMERS

- Saved up to $1M in potentially lost production

- Downtime avoided – increase reliability by10%

- Cost avoided – reduce repair costs by 5%

USED BY

- Process engineers, control room technicians, maintenance engineers, production managers, and shift leaders

- Access: SaaS (Software as a Service) via a web browser (Chrome or Firefox preferred).

- Frequency of access: Usually once or twice a day.

- Alerts via SMS/Email: Available through push to the organization’s notification distribution system (subject to acquiring an annual subscription license).

DATA INTEGRATION

YOU ALREADY INVESTED IN DATA COLLECTION

Most plants are already collecting sensor data into a historian. SamGuard allows you to leverage this investment and maximize your knowledge from your existing data.

Supported Historians (via file transfer)

- OSISoft PI

- Aspentech PIMs

- IBA

- Siemens, GE

Available Integration Methods

- File transfer

- SQL

- Web

- API

Number of tags per plant supported by the solution:

From 100 to 10000s historian tags per plant

IMPLEMENTATION REQUIRMENTS

Cloud-based or on your corporate network

SAM GUARD can be installed on any Virtual Machine running Linux. Space can be provided on our server or install the application on your own servers. Make your own choice!

UNIQUE COMBINATION OF AI AND HI (Human Intelligence)